How Seasonal Changes Can Affect Print

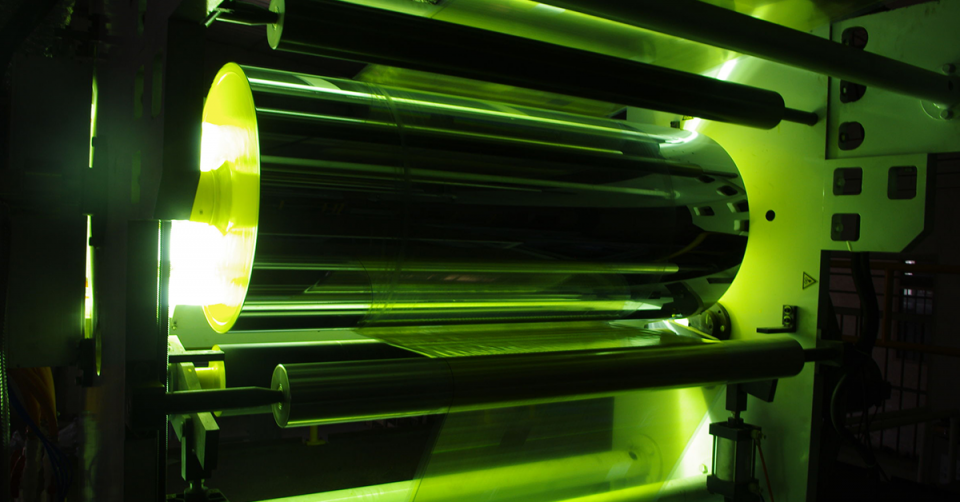

It’s summertime, and extreme temperatures can have a dramatic effect on your printing process. Drying rates of coatings are often slower whenever an excessive amount of heat and moisture is present. Since paper stocks, inks, and coatings are all affected by heat and moisture, proper care should be taken to deliver a saleable press sheet.

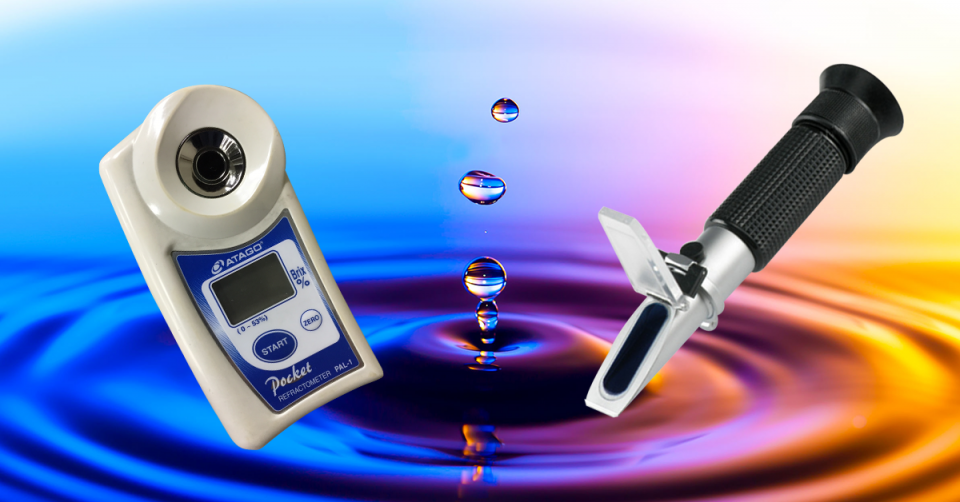

Process control of all variables in the printing process is critical when conditions are extreme. Pile temperatures, coating viscosity, film weight, ink emulsification, ink density, and fountain solution conductivity should be closely monitored.

Maintaining the recommended pile temperatures during printing is critical. A combination of infrared energy and warm air are needed. The shearing and removal of moisture from the sheet is