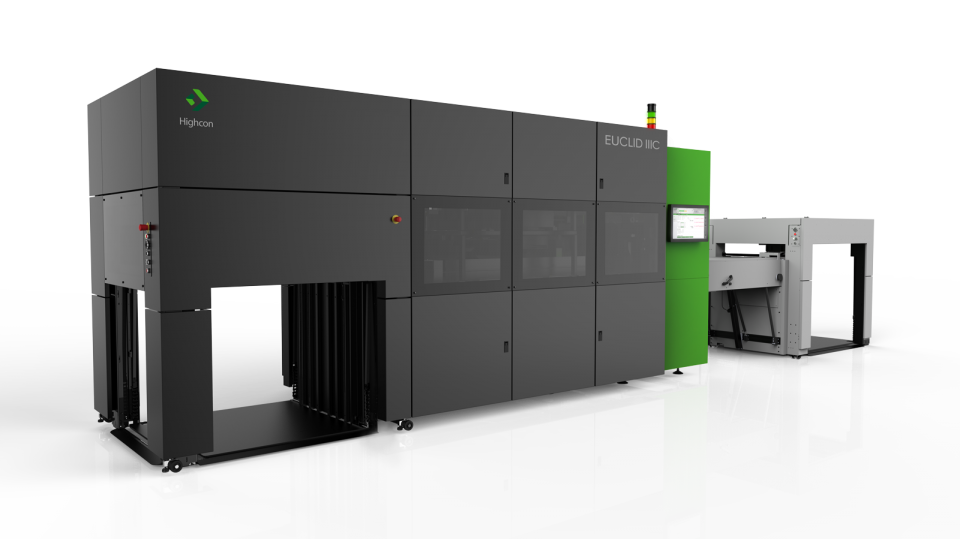

Highcon Euclid IIIc

The Highcon Euclid IIIC digital cutting and creasing machine has been specifically engineered to suit the needs of packaging converters working with corrugated and fluted substrates in B1 or B2 format for corrugated and fluted substrates from 1 mm up to 3mm / 40-120pt.

Not only does the Highcon Euclid IIIC save on the production and storage of die cutting forms but also adds the flexibility of digital technology which enables JIT production, short runs, customized perforations with cleaner edges and easier opening, and variable data etching for customization or personalization down to the level of serial numbers.

Box Compression Tests that have been performed by comparing the digitally produced boxes with conventional ones have proven that boxes produced with the same substrate on the Euclid are stronger than those produced on conventional machines – and this enables thickness reduction that saves costs.

Benefits

- Ability to customize size and structure to optimize box size, reducing shipping costs

- The flexibility of digital technology enables JIT production, short runs, customized perforations with cleaner edges

- Customized perforation capability enables optimized opening mechanisms

- Box Compression Tests prove that boxes produced with the same substrate on the Euclid are stronger than those produced on conventional machines enabling thickness reduction that saves cost

Features

-

Flute and microflute range: N, F, G, E & B (single wall, laminated)

-

Up to full B1/ 42 in. format

-

Up to 1,500 sheets/ hour

-

Advanced Registration (optional) printed mark required on top

-

Variable data cutting (optional)